No.8 Mirror Surface Grinding Machine

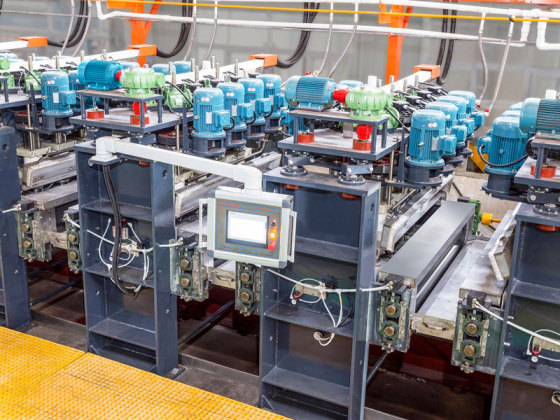

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

No.8 Mirror Surface Grinding Machine

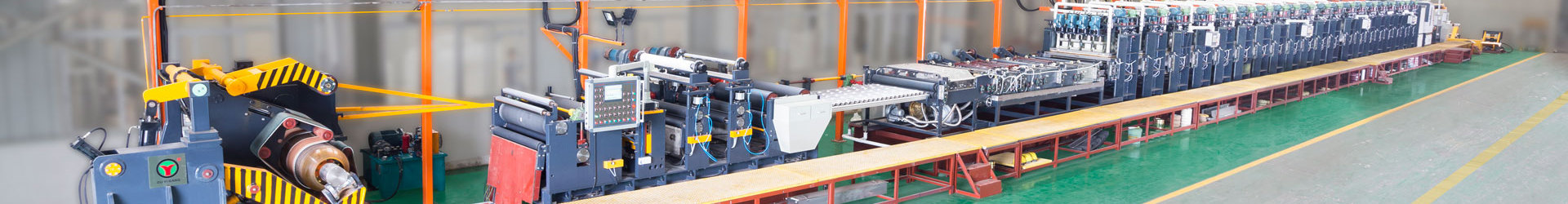

OUYIGANG machinery performs automated and manual metal polishing services, for directional grain, non-directional grain and mirror applications.

To meet the growing demand, we specialize in polishing large size sheets and plates up to 144" wide and 420" long. We've also strategically developed a unique niche with our focus on 48" and 72" wide sheets. We offer #4 and #6 brush finishes lengthwise, cross-grain, or non-directional patterns. In addition to #7 dull mirror or #8 bright mirror finishes that are available on all shapes.

Upon request, we can deliver a complete range of Ra finishes with our current certifications. When it applies to a project, we can apply PVC film and laser tape as a protective coating.

The advantages

Key points of ① speed up and deceleration restart response speed ② emergency stop automatic protection of the board surface, the operation and use of personnel are not tired and safe ③ reduce plate waste, higher yield rate spare parts storage location savings, Reduce inventory overhang.

Environmental protection use of waste water to reduce 90% discharge, site layout is convenient for operators to control, safe production.

The 8K whole line grinding head layout is reasonable, the pressure is uniform and controllable, save 20% ~ 30% power consumption, greatly improve the grinding speed of 2 ~ 6 meters per minute, match the grinding effect of the board surface, ensure clear, uniform and bright, reduce energy consumption and cleaning costs, more effective control of the plating color plate, improve the yield.

The effective control of the subsection cleaning machine cleaning cleaner, cleaning waste water recycling better adjustment, replacement of water is not wasted, can reduce 90% of emissions.

The equipment has good control, high efficiency, energy saving, environmental protection, excellent value, good cleaning and maintenance, good maintenance, fast replacement parts, strong practicability, high cost performance, is the ideal product for investors.

Cost savings.

Processing capability

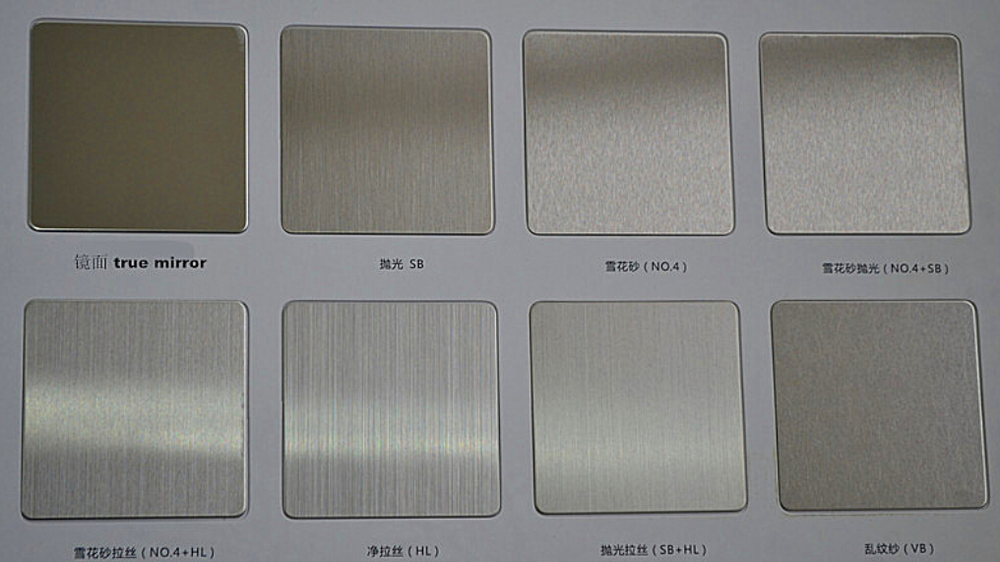

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

No.9 super mirror finish

Very high degree of reflectivity, brilliant, smooth finish produced by polishing with progressively finer grit abrasives then buffing. Super mirror creates light and space. Best for design, decoration and architecture.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.