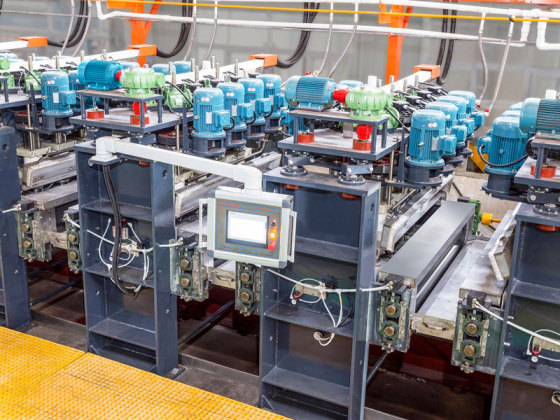

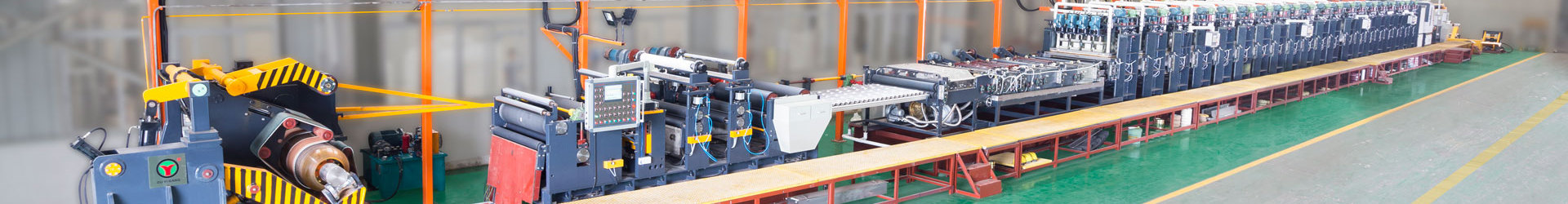

Mirror Stainless Steel Coil Grinding Machine

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Mirror Stainless Steel Coil Grinding Machine

Metal Polishing Services

OUYIGANG machinery performs automated and manual metal polishing services, for directional grain, non-directional grain and mirror applications.

We offer #4 and #6 brush finishes lengthwise, cross-grain, or non-directional patterns.

In addition to #7 dull mirror or #8 bright mirror finishes that are available on all shapes.

Upon request, we can deliver a complete range of Ra finishes with our current certifications. When it applies to a project, we can apply PVC film and laser tape as a protective coating.

Processing capability

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

No.9 super mirror finish

Very high degree of reflectivity, brilliant, smooth finish produced by polishing with progressively finer grit abrasives then buffing. Super mirror creates light and space. Best for design, decoration and architecture.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: Foshan

Province:Guangdong

Country:China

FAQ

Q1. How to get the most suitable polishing machine and best price

A: Please tell the material you want to working on? and the specification of your working material?

Q2. Do you have the manual of the polishing machine Except the automatic machinery?

A: Yes, we have.

Q3. If we don’t know how to use the polishing machine, can you teach us?

A: our customer support engineer will go to cutomer's factory to install the machine , and they will teach the skilled labor complete knowledge about the machine.

Q4. Do you have the machinery applying to the special steel sheet?

A: When the sheet thinckness comes to 4mm and more then 4mm, or there is some special performance to your sheet,it is suggested that the customer come to our company talk about the technical requirement with our engineers.

Q5. What is the useful life of your machine?

A: The useful life of the equipment depend mainly on the maintainability, and our machine can be used for more then 6 years ,most of it come to above 10 years under normal operation and maintenance.