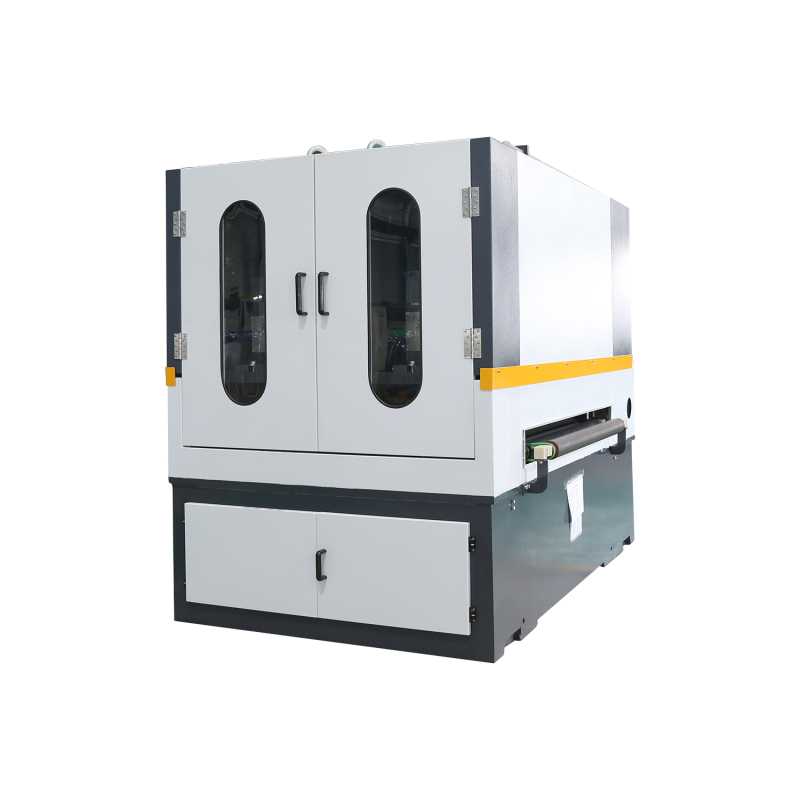

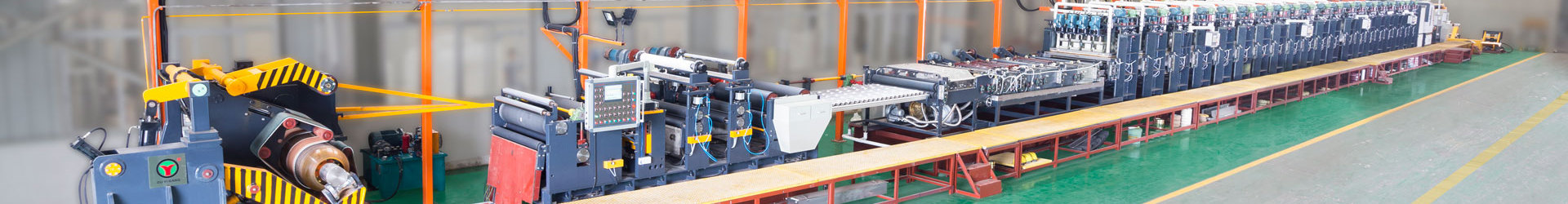

Metal Sheet Grinding Machine

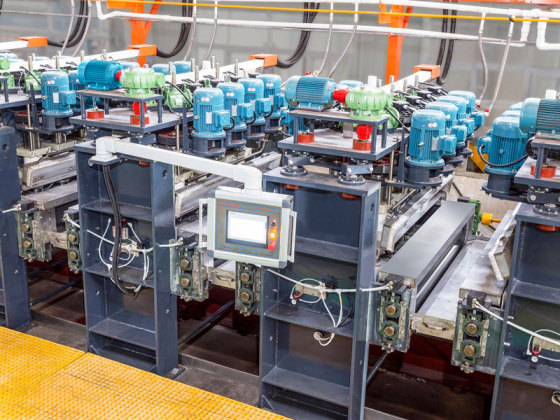

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Metal Sheet Grinding Machine

Product Description

The polishing of coils and sheets is one of the most value added operations offered by service centers. Perfect machinery is the key to success in every business, OUYIGANG grinding/ polishing machines are very easy to achieved Matt, Hair -Line, Satin, No.4,No.6 finish. OUYIGANG Metal Surface Polishing Machines can be applied to the top surface of coils and sheets. We are the leading company in the metal processing equipment , our machine cover more than 70% of the Chinese market and is going to meet the worldwide challenge with its extraordinary performance and innovative technology.

Basic specification for the machine

Belt abrasive station | No.4 | Hairline | |

Brush abrasive station | SB | ||

System | Wet roller grinding | Wet roller brushing | Wet roller grinding |

No. of working unit | 2-3 grinding heads | 2-4 polishing heads | 2-3 grinding heads |

Machine weight | Appro 13T | 11T | 13T |

Working width | 900,1250,1500mm, , customized available | ||

Sheet size | 1250X2500mm 1550X3000mm customized available | ||

Sheet thickness min / max | 0.3-4mm | 0.3-4mm | 0.3-4mm |

Roller dimensions(Od X width) | 300mm | 350mm | 250mm |

Abrasive belt width | Depending on the sheet width

| ||

Abrasive belt length | 2620mm | 2620mm | |

Speed of the line | 6-25M/min | 6-25M/min | 6-25M/min |

Processing capability

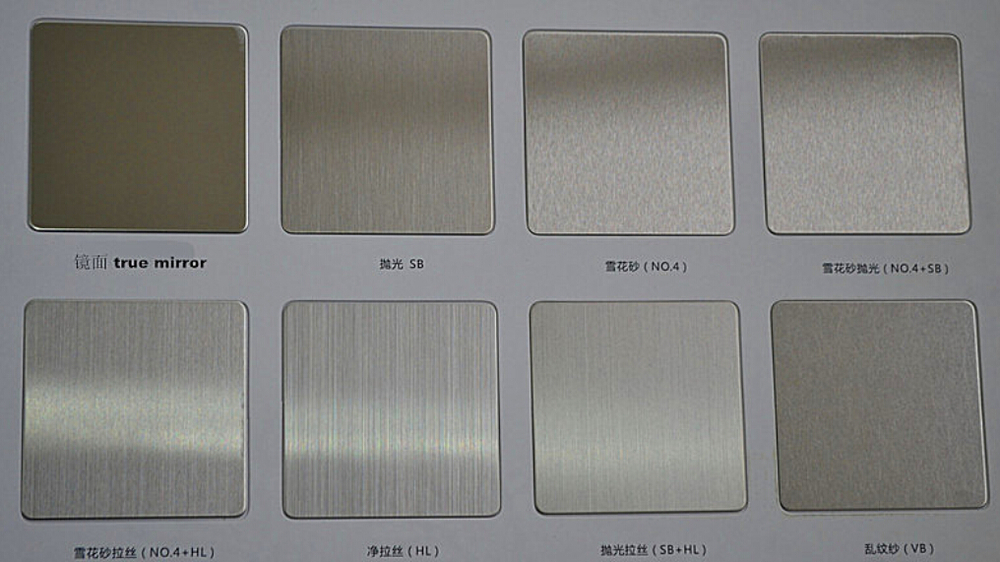

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 true mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

No.9 super mirror finish

Very high degree of reflectivity, brilliant, smooth finish produced by polishing with progressively finer grit abrasives then buffing. Super mirror creates light and space. Best for design, decoration and architecture.

Equipment Features

Multi head brushing station, “all in one line ” equipment with No.4—No.6 , Scotch-Brite , Hairline finish

Control by PLC complete with touch screen

Most of the inside construction is made of tempered stainless steel

Horizontal axis rotating and oscillating system

Soft, bright and homogeneous surface appearance

oil and water mixed ,wet type processing

Adjustable brushing pressure

Adjustable brush speed

Easy abrasives brush roller replacement

Adjustable conveyor speed (belt / roller)

Different brush grits combinations are possible to perform different surface treatment

Emergency security switch

Reversal conveyor speed for emergency control

Cooperation company

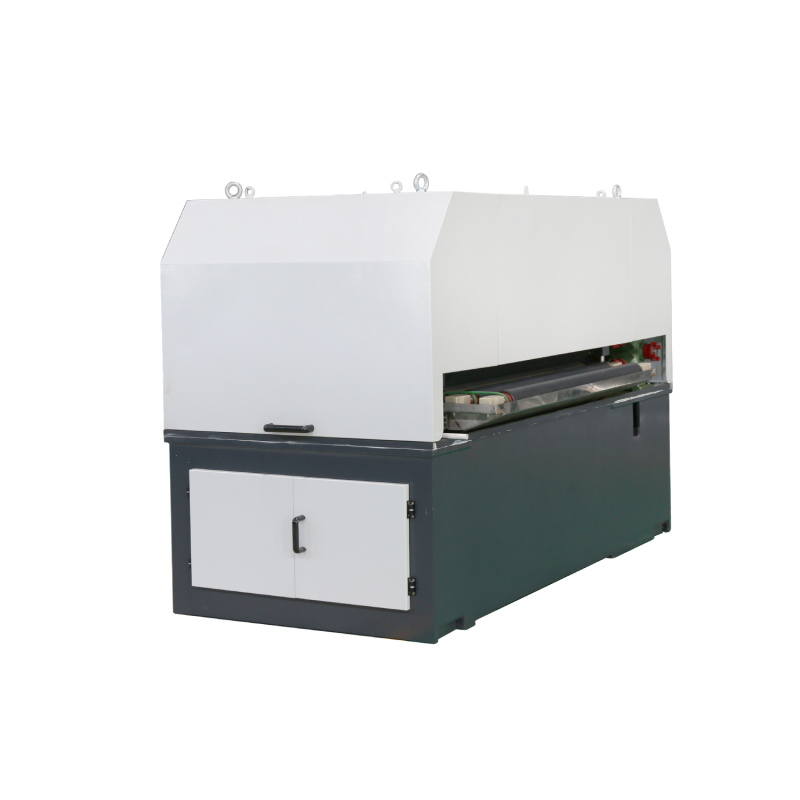

Advantages: The whole line design concept is unique.

The equipment has good control, high efficiency, energy saving, environmental protection, excellent value, good cleaning and maintenance, good maintenance, fast replacement parts, strong practicability, high cost performance, is the ideal product for investors.

Sander sand belt line speed of 40 meters per second, greatly reduce the cutting oil and sand belt, improve the grinding speed of 40 to 50 meters per minute, matching the grinding effect of the board, to ensure that the sand grain is clear, uniform and bright, good three-dimensional texture, reduce the cutting oil, sand belt and cleaning costs, more effective control of plating color plate, improve the yield.

Hairline machine adopts ring sand belt, cutting fluid spray drawing, better protection of the board surface, thickness and fine sand number matching is selective, quick replacement, improve the board surface sand pattern clear and uniform, to meet customer market demand.

No.4 polishing machine adopts a diameter of 400 grinding head, improve the grinding effect, increase the frame and rigidity, ensure stability, improve the grinding efficiency, the board does not vibration pattern uniform bright, sand texture is good, to reach the industry leading equipment.

The whole line synchronization is stable, easy to operate, fast in and out of the board, the board head and tail control in the range of 600 ~ 1000mm effective grinding, high efficiency and energy saving, speed up and deceleration response speed, emergency stop automatic protection of the board, the operation and use of personnel are not tired and safe.

Contact us

Tel:86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: FoShan

Province:GuangDong

Country:China