- Home

- >

- Products

- >

- No.4 Buffing Machine

- >

No.4 Buffing Machine

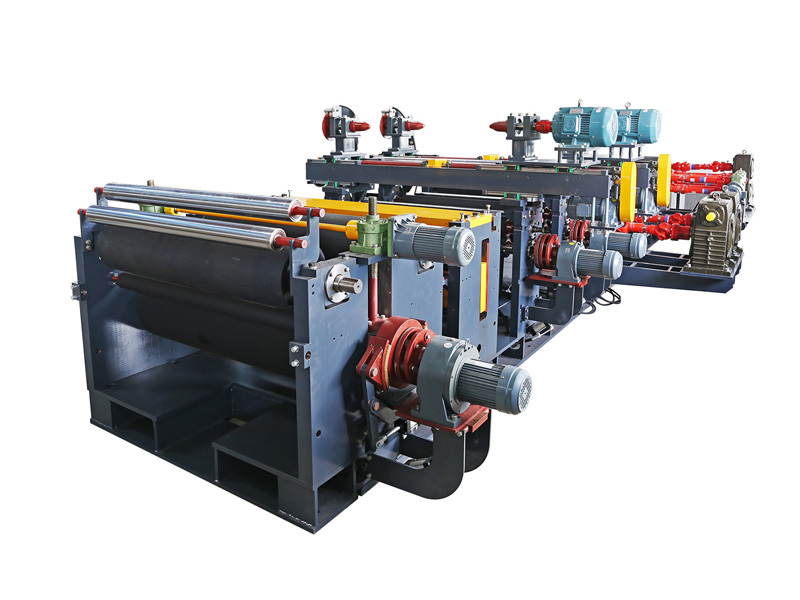

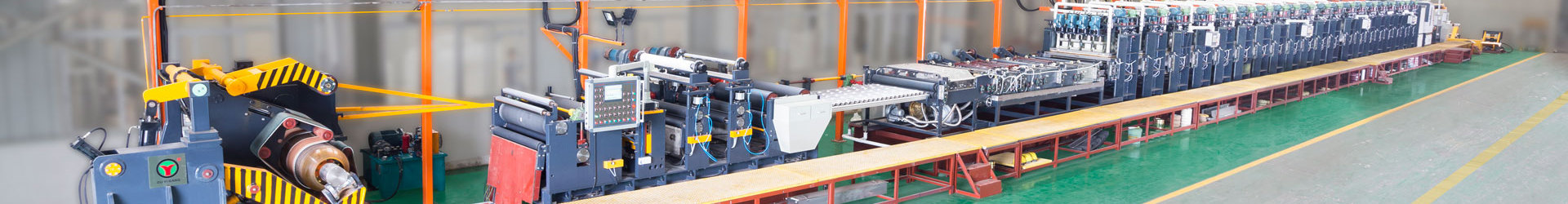

1. The whole line is synchronous, stable and easy to operate, the feeding and un-loading is quick and efficient, and the response speed is fast. The emergency stop automatically protects the board surface.

2. The whole floor area is reasonable in design, the basic project is simple and practical, to cut down the cost of engineer, the whole line with recycle system, meet the requirement of environment zero emission, and it is convenient for operators to control and safely produce.

3. The production line can be ground flat or wound, the utilization rate is high. And the automation is high, only two operators are needed.

4. Sanding machine belt line speed of 50 meters per second, greatly reducing cutting oil and abrasive belt, increasing the maximum speed of the grinding board to 60 meters per minute, matching the surface grinding effect, ensuring clear and uniform sanding,reducing cutting oil, abrasive belt and cleaning costs.

5. The straight line drawing machine is matched with the annular abrasive belt, the cutting fluid is sprayed and brushed, which better protects the board surface. The thick and fine sand number is matched with selectivity, the replacement is quick, and the sand surface of the board surface is clear and uniform to meet the customer market demand.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

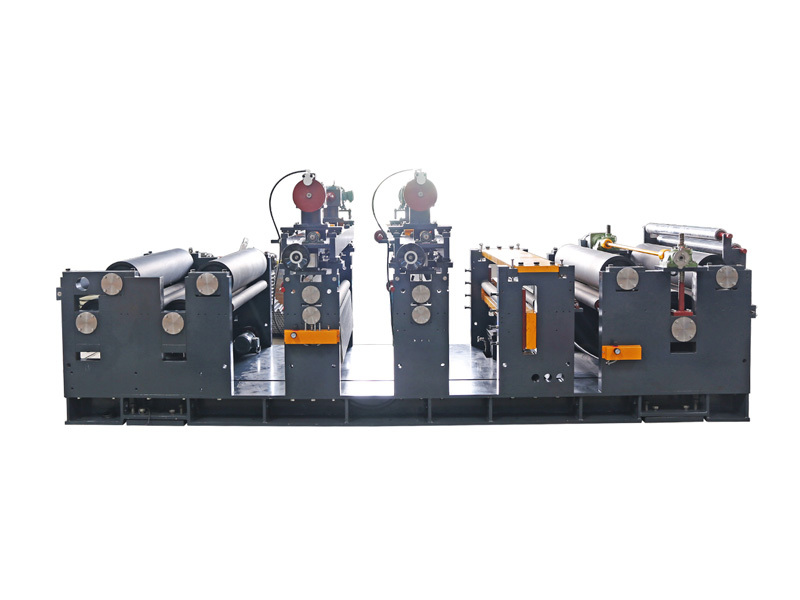

No.4 Buffing Machine

Function and characteristic

1. It applies to grinding the surface of 0.4mm-3.0mm 2B. BA stainless steel sheet, making the sheet have scotch bright effect.

2. Delivery with rolling wheel, motor variable frequency adjusting the speed, roll synchrodrive

Via the worm reduction box, deliver smoothly, preventing the sheet slip during the processing.

3. The floor of the platform is made up of organic toughened glass, increasing its working life.

4. Reasonable design to the point control part, it is more reliable and safer.

5. The material for swing parts is specially treated, having excellent wear-resistant

6. Refining grinder is made of A-alloy, so as to achieve the effect of corrosion-resistant, acid-resistant, wear-resistant.

| Plate thickness (mm) | 0.4~3.0 | 0.4~3.0 |

| Plate width (mm) | 1250 | 1550 |

| Speed (m/min) | 6~60 | 6~60 |

| Coil outer diameter (mm) | 1900 | 1900 |

| Coil inner diameter (mm) | 508 (610) | 508 (610) |

| Uncoil bearing (T) | 22 | 25 |

| Length of production line (mm) | 37 | 39 |

| The total power unit (KW) | 465 | 568 |

Component parts

1.Unwinding Machine

2.Pinch Leveling Cutting

3.Paper Collecting Unit

4.Auto Feeding Table

5.Bottom side NO.4 Polishing Machine

6.NO.4 Polishing Machine

7.Hairling Machine

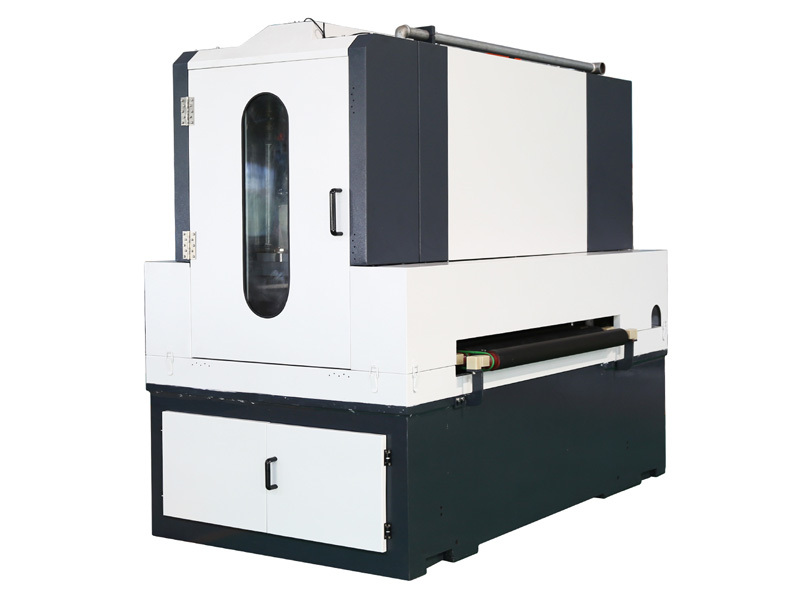

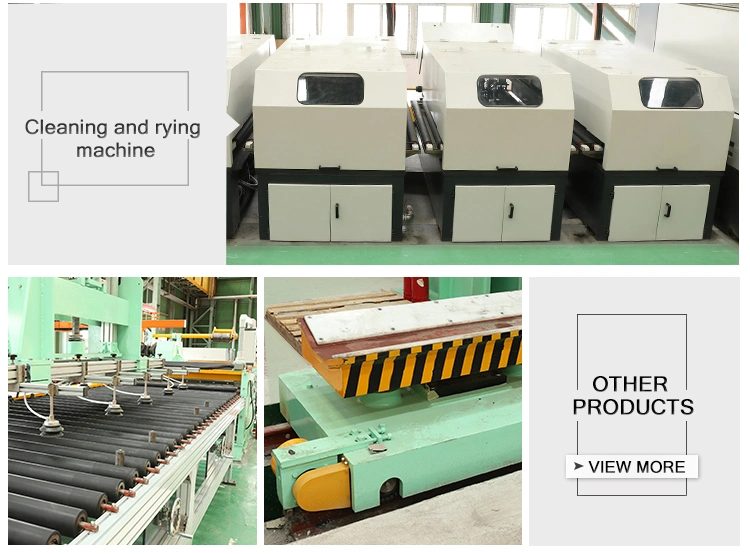

8.Cleaning and Drying Machine

9.Fully Auto Laminator

10.Auto Unloading Table

11.Tension Device (Including CPC)

12.Recoiler

Contact us

Tel:86-757-88627213

Mobile phone:+86-13425703089

Address detail :No.19,Xingliang Road, Sanzhou Town, Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

City: FoShan

Province:GuangDong

Country:China