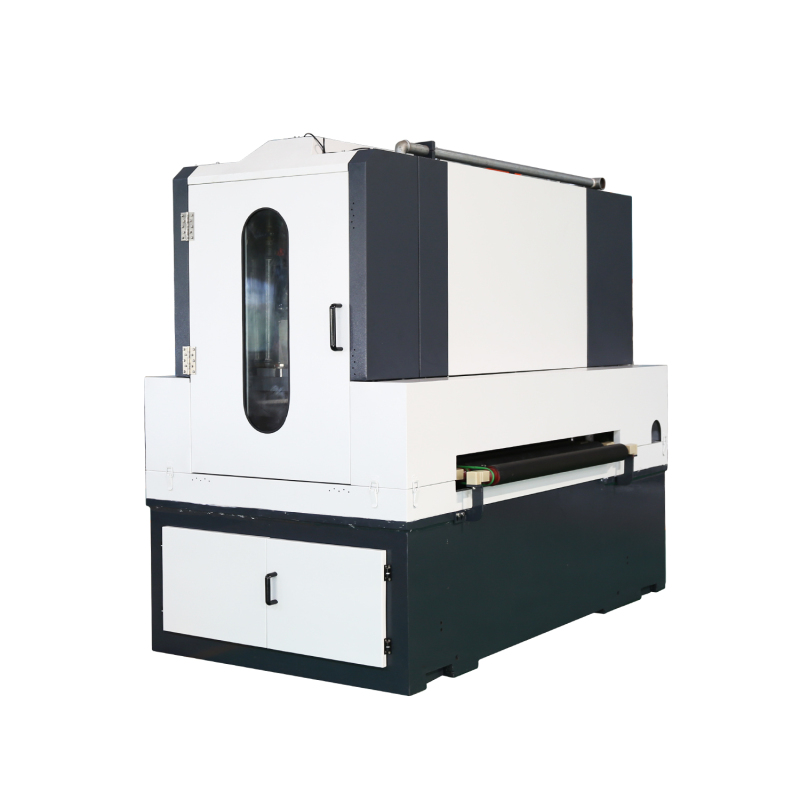

NO.8 Buffing machine for Stainless Steel Coil

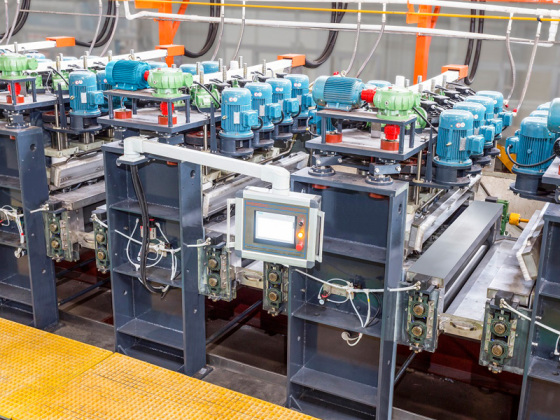

The synchronization of the whole line is stable, the operation is simple, the board input and output are fast, efficient, and the response speed is fast, and the emergency stop automatically protects the board surface.

The area of the whole line is reasonably designed, the basic engineering is simple and practical, the engineering cost is reduced, the site layout is convenient for operators to control, and the production is safe.

High automation, only need two operators, high efficiency.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

NO.8 Buffing machine for Stainless Steel Coil

Product Description

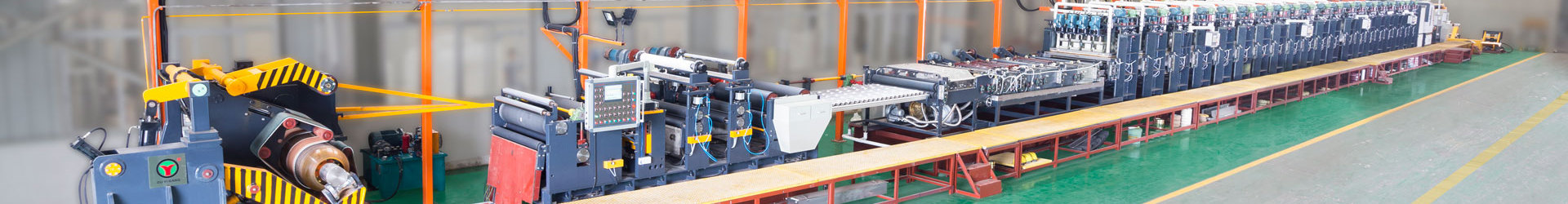

Stainless steel coil or sheet 8k super mirror polishing production line

Product Details

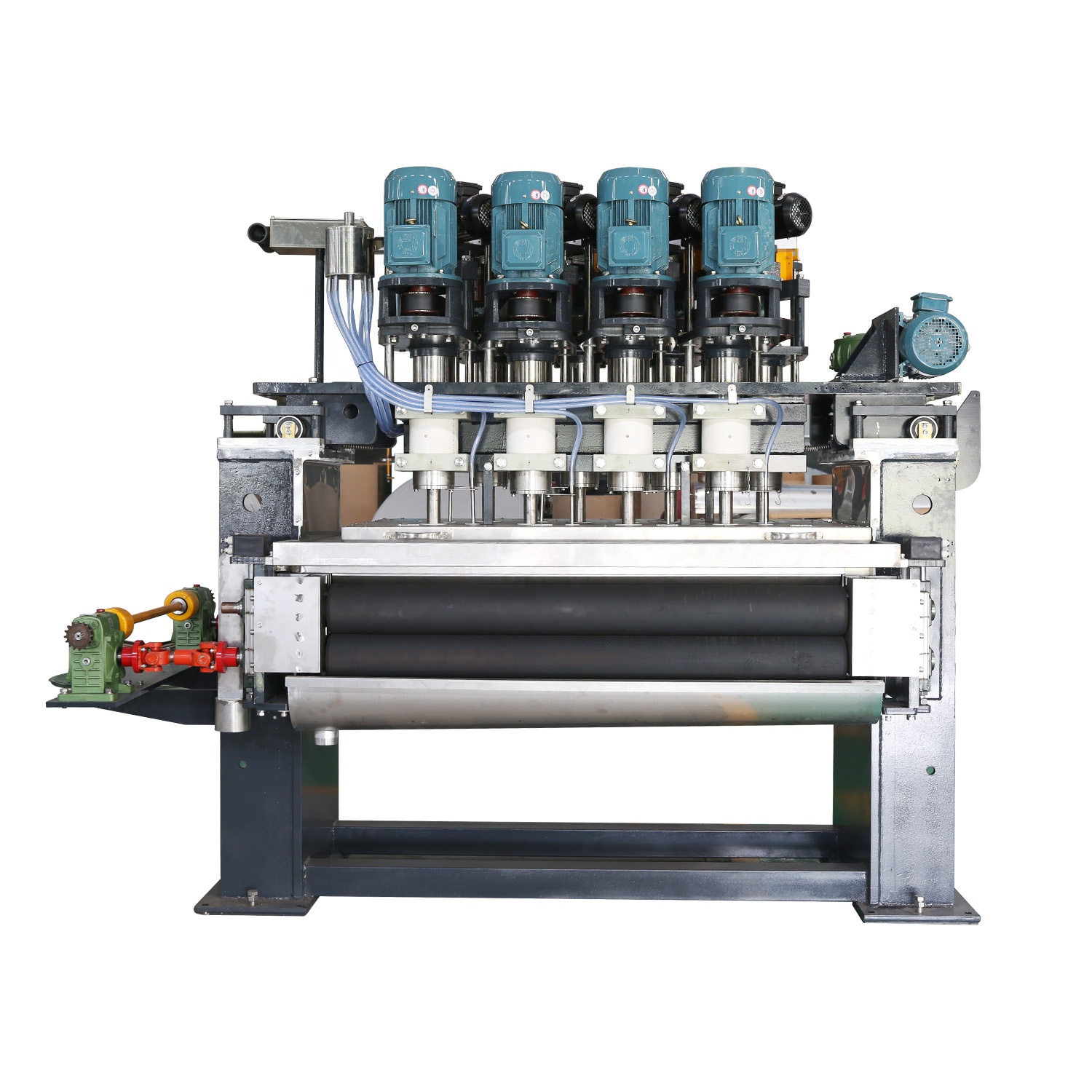

It includes one single head polishing main machine

Packing and Delivery

Packing type: nacked package, shipped with steel container

Delivery date: 30 days after receiving the deposit

Appplicalbe stainless steel sheet specification

Processing Width (mm) | 1000~1550 max |

| Feeding speed (m/min) | 1.5 |

| Coil thickness (mm) | 0.3~2.0 |

| Sheet thickness (mm) | 0.6~3.0 |

| Grade of sheet | JIS200,300 series |

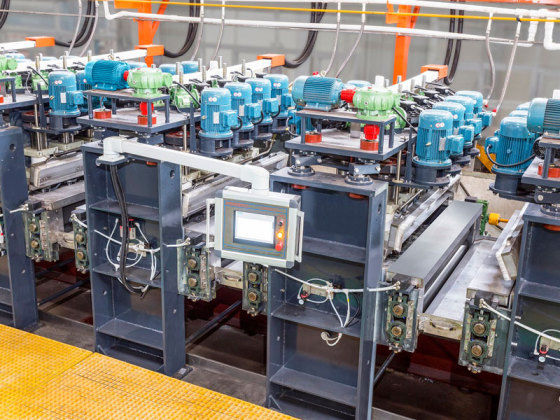

Technical specification for stainless steel sheet 8k mirror finish polishing machine

What is the fountion of this single head polishing machine ?

Can be used to process stainless steel sheet surface to get no.6,no.7,no.8,nuclear,BA,bright,ultrabright, mrirror finish

Product Advantage

The advantages

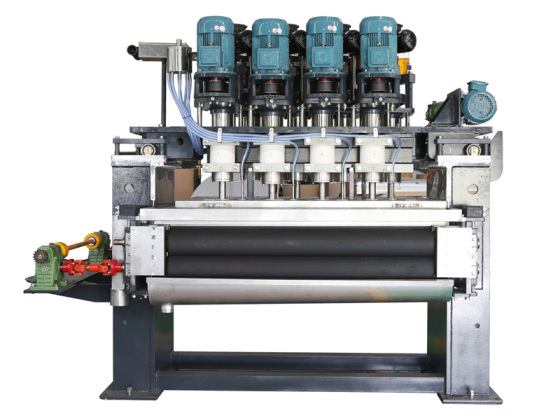

The whole line drive motor, grinding head motor, clamping roller and force roller, driving roller and film roller, leveling roller and bottom roller, excessive roller, worm gear reducer, connectors, cardan shaft, bearing seat, clamping roller pressure cylinder, acid water pump, glass bottom plate, multi-pit belt, filter paper, exchange common spare parts to customers to save a lot of costs, purchase time to save a lot of manpower and material resources, Spare parts storage location savings, reduce inventory backlog funds.

The synchronization of the whole line is stable, easy to operate, fast in and out of the board, the board head and tail connection control within the range of 600mm effective grinding, efficient key ①, speed up and deceleration restart response speed ②, emergency stop automatic protection of the board surface, the operation and use of personnel are not tired and safe ③ reduce plate waste, higher yield.

The whole line covers an area of reasonable design, basic engineering is simple and practical, reduce engineering costs, environmental protection use of waste water to reduce 90% discharge, site layout is convenient for operators to control, safe production.

The 8K whole line grinding head layout is reasonable, the pressure is uniform and controllable, save 20%~30% power consumption, greatly improve the grinding speed of 2 ~ 6 meters per minute, match the grinding effect of the board, ensure clear, uniform and bright, reduce energy consumption and cleaning costs, more effective control of the plating color plate, improve the yield.

Subsection cleaning machine effectively control cleaning cleaner, cleaning waste water recycling better adjustment, replacement of water is not wasted, can reduce 90% of emissions.

The filtration system is clean, energy saving, automatic control, easy to clean, small footprint, acid concentration is easy to adjust, save the best equipment with acid.

The equipment has good control, high efficiency, energy saving, environmental protection, excellent value, good cleaning and maintenance, good maintenance, fast replacement parts, strong practicability, high cost performance, is the ideal product for investors.

Key advantages processing per square meter of sheet metal saves 0.5 ~ 1.0 yuan of cost compared with other manufacturers, different thickness of the annual processing of about 8000-12,000 tons of output value, saving nearly 600,000 ~ 1.5 million yuan of operating costs annually.

Save the cost of environmental protection of nearly 1 ~ 2 million yuan a year, the equipment is stable, the operation is simple and safe, manufacturing enterprises to find a strong earning ability of the equipment is the truth.

FOSHAN OUYIGANG engaged in design and manufacturing the stainless steel surface processing machinery,the factory of OUYIGANG occupies above 10000 square meter, we are the high-tech company of more than 20 years production history, which gather science research,design,produce,sale install,adjust and maintenance.

Our company culture: loyalty,dedication, hard-work and cooperation

Company philosophy:Constant cooperation and mutual benefit, to create greater value for our customers.

Our service concept: Your little case is our big events.

The miss of our company: To pursuit perfect quality, then provide professional service.

Company vision: Building one centennial corporation, setting one international brand.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :

Factory No.19,Xingliang Road,Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

Province:GuangDong

Country:China