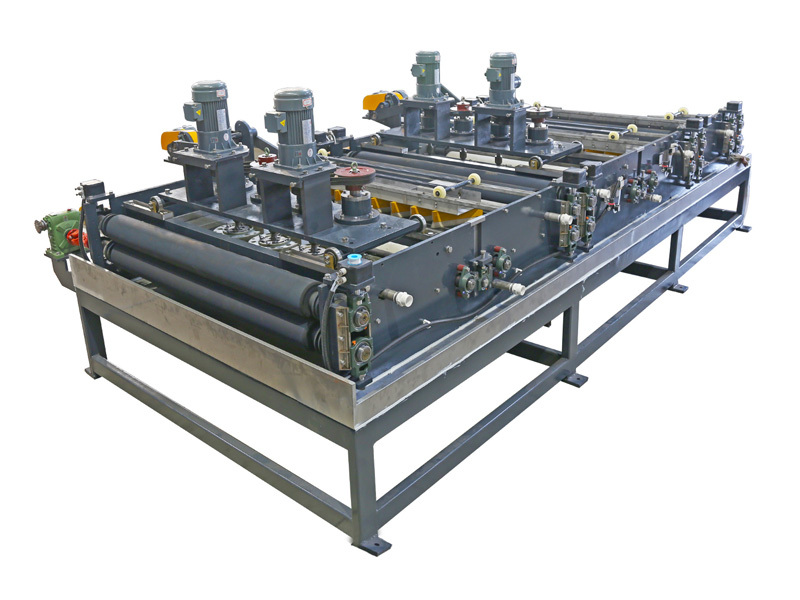

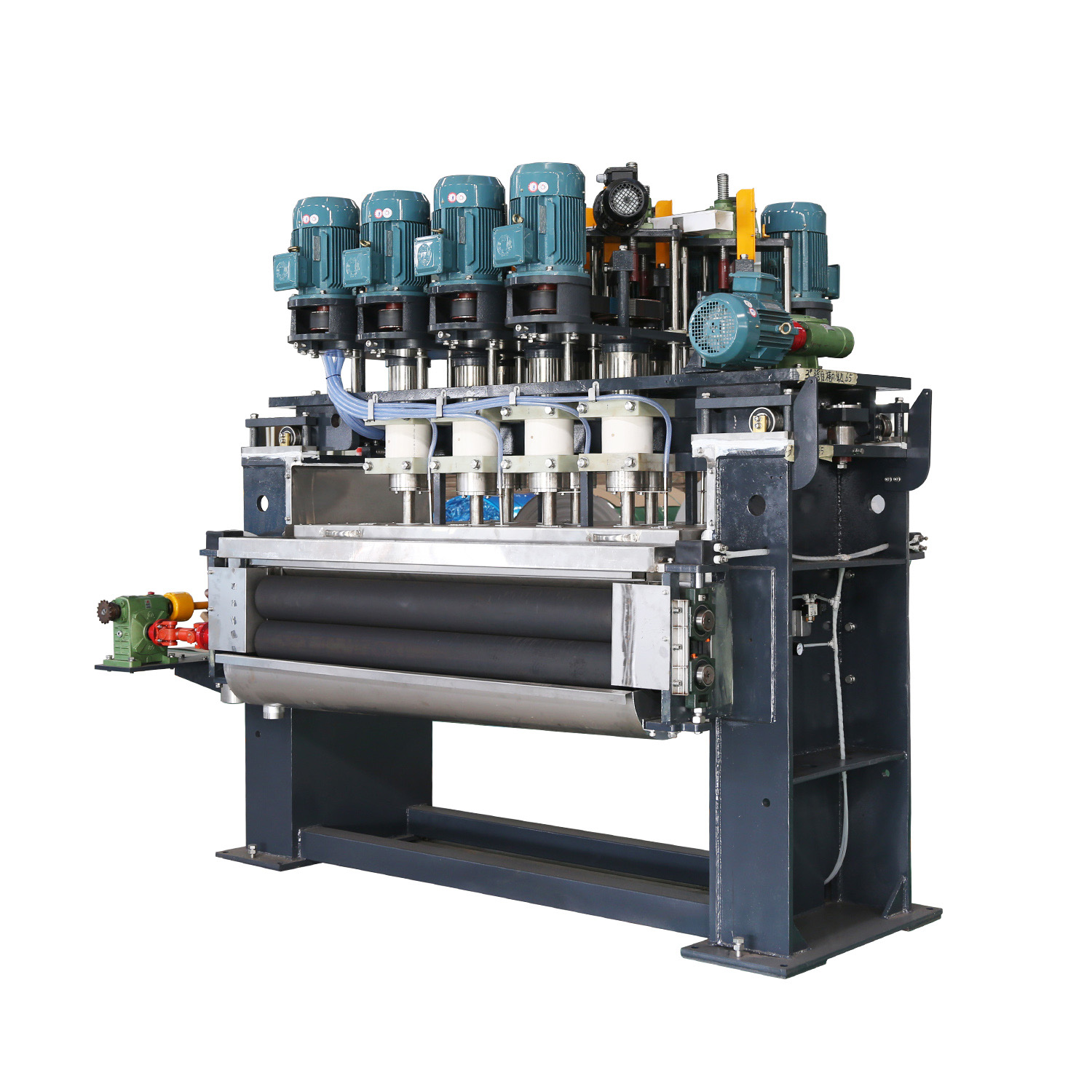

Mirror buffing machine for Stainless steel sheet

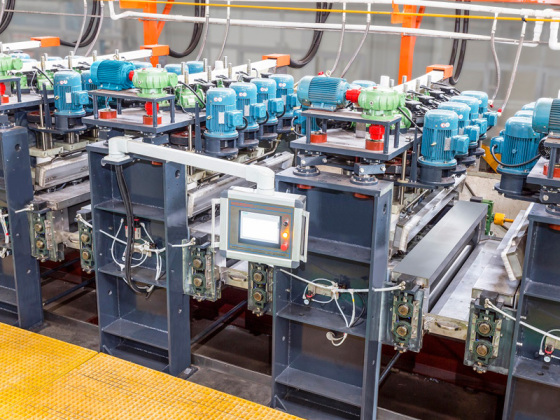

Combining foreign advanced design concepts and cutting-edge technology, using Siemens functions to develop a patented CNC operating system, it is the future trend of metal surface processing equipment, with automation, high efficiency, energy saving, safety, stability and other characteristics.

After years of research and development, combined with the actual use of a number of patented technologies of our company, it has the characteristics of automation, high efficiency, energy saving, safety and stability.

- OUYIGANG

- FOSHAN

- One Months

- 1 Set/ Month

- Information

- Video

Mirror buffing machine for Stainless steel sheet

Technical specification for stainless steel sheet 8k mirror finish polishing machine

Appplicalbe stainless steel sheet specification

| Sheet thickness(mm) | 0.6~3.0 | 0.6~3.0 |

| Sheet width(mm) | 1250 max | 1550 max |

| Processing speed (m/min) | 0.5~1.2 | 0.5~1.2 |

| Grade of sheet | 430,439,445,304,316,200 series | 430,439,445,304,316,200 series |

Packing&Delivery

Packing type: nacked package, shipped with steel container

Delivery date: 30 days after receiving the deposit

What is the fountion of this single head polishing machine ?

Can be used to process stainless steel sheet surface to get no.6,no.7,no.8,nuclear,BA,bright,ultrabright, mrirror finish.

Product Advantage

1. Original and unique design

OUYIGANG Machinery have unique and advanced machine design. It is matching on good material and high-configuration design: Safe, quick, practical and etc that different style for steel processing, welcome to contact us for more information about new design.

2. High & stable quality

OUYIGANG Machinery is from material purchasing, and the whole producing, we guarantee customers “high quality, stable quality”. Our products had passed CE certification, ISO9001-2008, ISO14001 and other quality test report. third part inspection is available whenever it is requested.

3. Well material

OUYIGANG Machinery are produced with well material by high technology, environmental, long service life and safe. It will always create to you a comfortable and reassured work life.

Excellent quality from material to finish product

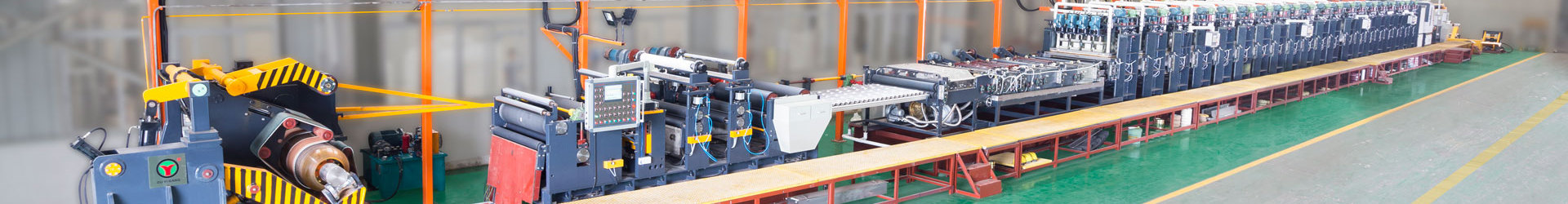

OUYIGANG is technologically advanced machinery that compared to other alternative products, strictly quality controllers and strongly supervises the quality from material purchasing, compare, test and then decide the original material which is satisfied customer request. During the producing, we must be following closely to make sure the quality is excellent and is same as our confirmed sample. OUYIGANG can be supplied in sheet to sheet ,coil to coil and even cut to length ,for this last option, OUYIGANG has PUR technology in order to offer its product the finish according to its quality.

World Class Expertise

We offer our clients world class insight, intelligence and expertise on a local, regional and global scale. Considered as authorities in their field, many of our experts reside on international committees that formulate the next practices with regard to international standards. These insights enable our experts to provide our customers with practical advice based on best practices and foresight knowledge.

Dedicated customer services

We feel honor to serving you with sincere .We continue to build on existing customer relationships to provide dedicated customer services. With a strong group of service engineers of talents dedicated and omitted to OUYIGANG philosophy, competence, rigorous and creative. We have strengthened our position as the leader in the industry.

We focus to solve our customers' most difficult problems promptly and efficiently. Our customers satisfy in applying OUYIGANG machinery.

Local government policy support & perfect industrial zone resource

Our company located in SHUNDE district, FOSHAN city, SHUNDE is one of Chinese biggest and famous stainless steel industrial town, and our factory surrounded by mounts of stainless steel processing company, and we are based on a stainless steel industrial zone, which supported by SHUNDE local government policy from electricity ,material to transport.

Overall Processing capability

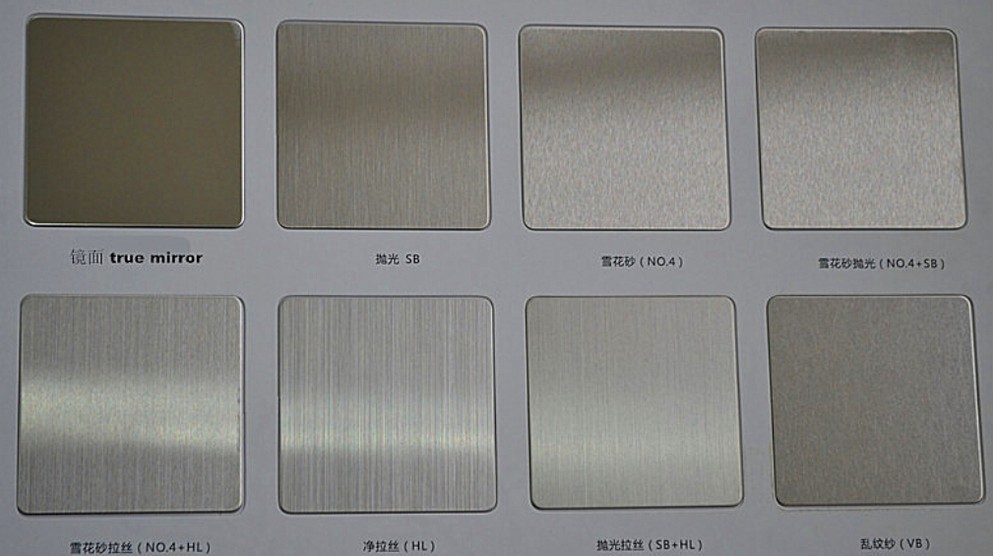

No.4 finish

The basic sheet selection is to be of 2B or BA sheet and should be preferably polished with 150#,180# abrasive belt. The application verticals of this finish to name a few are in cookware, furniture, elevator, architectural decoration, revolving door, exterior decoration etc,.

HAIRLINE finsh

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with 150# 240#abrasive belt. The application verticals of this finish to name a few are in elevator, architecture decoration, revolving door, furniture, home appliance, auto sector, exterior decoration, etc,.

Scotch Brite-Satin finish

The basic sheet selection should preferably be of No.4 satin surface stainless steel sheet and should be subjected to polish with abrasive wheels or pads. . The application verticals of this finish to name a few are in architecture decoration, elevators and escalators, furniture, etc,.

No.6 finish

These finishes are produced using rotating cloth mops (tampico fibre,muslin or linen) which are loaded with abrasive paste.The finish depends on how fine an a abrasive is used and the uniformity and finish of the original surface. The finish as a non directional texture of varing reflectivity.Satin blend is an example of such a finish.

No.7 finish

This is a buffed finish having a high degree of reflectivity.It is produced by progressively using finer and finer abrasives and finishing with buffing compounds. Some fine scratches may remain from the original starting surface.

No.8 mirror finish

This is produced in an equivalent manner to a No.7 finish, the final operation being done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is the true mirror finish.

Cooperation company

Our Services

After-sale service:We supply life time technique service to our customer and just charge basic cost for comsumable parts.

FOSHAN OUYIGANG engaged in design and manufacturing the stainless steel surface processing machinery,the factory of OUYIGANG occupies above 10000 square meter, we are the high-tech company of more than 20 years production history, which gather science research,design,produce,sale install,adjust and maintenance.

Our company culture: loyalty,dedication, hard-work and cooperation

Company philosophy:Constant cooperation and mutual benefit, to create greater value for our customers.

Our service concept: Your little case is our big events.

The miss of our company: To pursuit perfect quality, then provide professional service.

Company vision: Building one centennial corporation, setting one international brand.

Company core value:

Observe disciplines and obey laws.

Conscientious and love in work.

Diligent and eager to learn.

Cooperation and innovation.

Contact us

Tel:86-757-88627213

Fax: 86-757-88627213

Mobile phone:+86-13425703089

Address detail :

Factory No.19,Xingliang Road,Hecheng Street,Gaoming District, Foshan City,Guangdong Province,China.

Province:GuangDong

Country:China