What's the effect of the New 8-12K mirror production line?

2026-02-02 17:53South China's First 1550 Type Coil to Coil 12K Mirror Production Line

Amid the wave of upgrading towards high efficiency, environmental protection and high precision in the stainless steel processing industry, Foshan City Ouyigang CNC Machinery Co., Ltd.has added another industry benchmark — South China's first 1550 Type Coil Grinding 12K Mirror Production Line was officially put into operation. This breakthrough equipment not only fills the gap in large-scale, high-precision coil grinding 12K mirror processing in South China, but also injects new vitality into the field with core advantages of "high efficiency, energy saving, low noise, environmental protection and easy operation". As a leading enterprise deeply engaged in CNC equipment R&D and manufacturing, Foshan City Ouyigang CNC Machinery Co., Ltd.has always been customer-oriented. The commissioning of the 1550 Type Coil Grinding 12K Mirror Production Line fully reflects the company's technical strength and innovation, providing global customers with high-quality and cost-effective stainless steel mirror processing solutions.

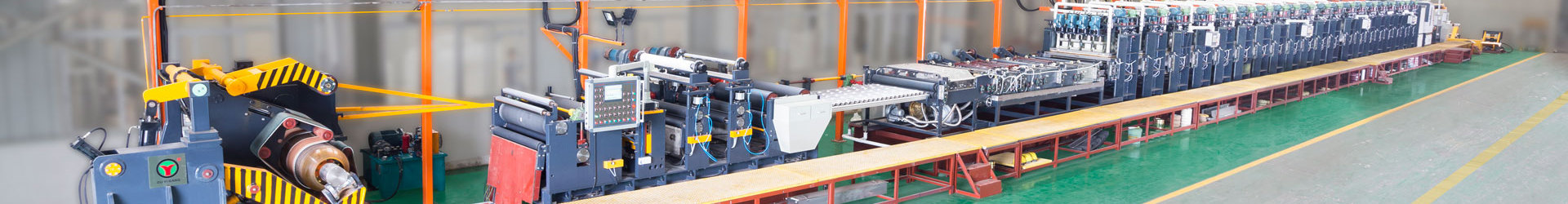

As a core flagship product of Foshan CITY Ouyigang CNC Machinery Co., Ltd., the 1550 Type Coil Grinding 12K Mirror Production Line reaches industry-leading levels in specification and performance. With a total length of 69000mm and a scientific modular layout, it realizes full-process automated operation from uncoiling, grinding, polishing to finished product coiling and film protection, greatly reducing manual intervention and ensuring stable and continuous processing. Notably, the uncoiler's maximum load-bearing capacity is upgraded to 25 tons, significantly higher than traditional equipment, easily adapting to mass processing of large-weight stainless steel coils, increasing single-batch output and reducing customers' production turnover costs. This core configuration makes the 1550 Type Coil Grinding 12K Mirror Production Line highly competitive in large-scale production, becoming the preferred equipment for batch processing.

High efficiency and energy saving are core highlights of the 1550 Type Coil Grinding 12K Mirror Production Line. The innovative design of 25 sets of main machines working synchronously breaks the efficiency bottleneck of traditional single-machine production lines. Controlled by an intelligent CNC system, the 25 sets of main machines realize parallel grinding and polishing, ensuring consistent processing parameters and uniform mirror effect on stainless steel coil surfaces. Its processing efficiency is more than 3 times that of traditional equipment. Meanwhile, equipped with energy-saving drive motors and optimized transmission structure, the equipment greatly reduces energy consumption while maintaining high efficiency, achieving dual advantages of high output and energy conservation, and helping enterprises realize green and low-carbon production.

The 1550 Type Coil Grinding 12K Mirror Production Line also excels in environmental protection and operability. Adopting a silent design with optimized mechanical structure and noise reduction components, it controls operating noise at an ultra-low industry standard, creating a quiet and comfortable working environment for operators and meeting modern factory noise reduction requirements. It adopts environmentally friendly processing technology throughout without harmful gas emissions, and combines with imported adhesive film protection to practice environmental protection in the whole process. In addition, the equipment features an intelligent touch interface, which is easy to operate — operators can master it proficiently after simple training, eliminating the need for professional technical teams and reducing labor costs and operation thresholds.

The 1550 Type Coil Grinding 12K Mirror Production Line has wide processing adaptability, covering stainless steel coils with thickness from 0.1mm to 6.0mm and width from 1000mm to 1550mm. It can achieve high-quality mirror processing for ultra-thin precision sheets, conventional thickness plates and thick industrial stainless steel plates. This flexibility stems from Foshan CITY Ouyigang CNC Machinery Co., Ltd.'s precise R&D and strict control of core components — every link is repeatedly tested and optimized to ensure finished products are of superior quality and excellent gloss, fully meeting the 12K mirror standard with smooth, scratch-free and high-reflectivity surfaces.

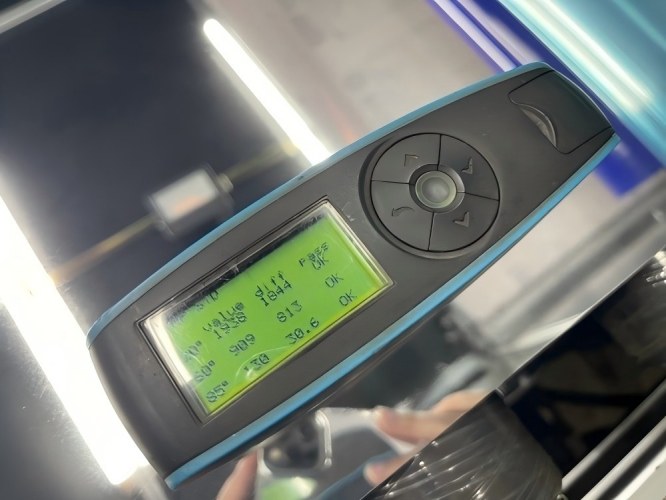

To ensure quality, Foshan City Ouyigang CNC Machinery Co., Ltd.has equipped the 1550 Type Coil Grinding 12K Mirror Production Line with an independent dust-free quality inspection room. Dust and impurities are key factors affecting mirror quality, and the dust-free room effectively isolates external interference. Quality inspectors use professional equipment to conduct multi-dimensional strict inspections on each batch of products, preventing unqualified products from leaving the factory and providing reliable quality assurance for customers.

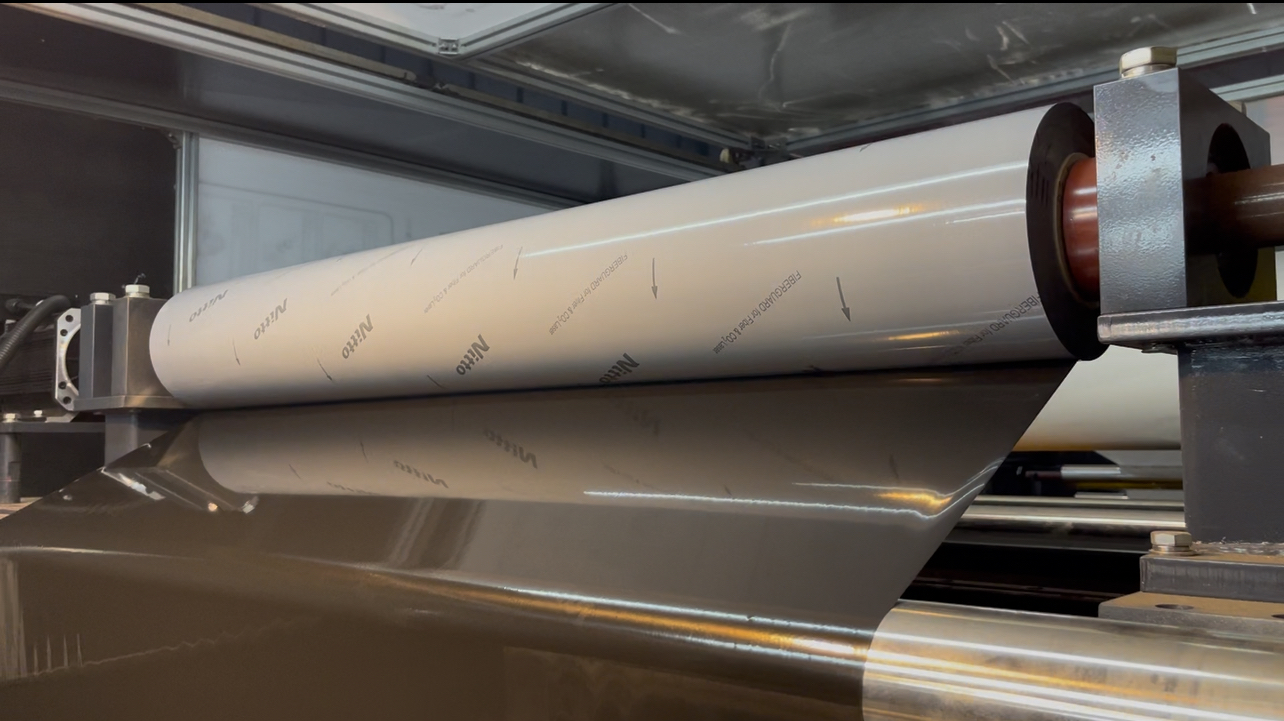

In the finished product protection link, the production line uses imported adhesive film to fully cover and protect processed stainless steel plates. The imported adhesive film has moderate viscosity, no residual adhesive, scratch resistance, water and moisture resistance, effectively avoiding plate damage during transportation, storage and subsequent processing, ensuring finished products are delivered in the best condition and reducing product loss and follow-up costs for customers.

The official commissioning of South China's first 1550 Type Coil Grinding 12K Mirror Production Line is an important milestone for Foshan City Ouyigang CNC Machinery Co., Ltd.and promotes technological upgrading of the regional stainless steel mirror processing industry. Integrating multiple advantages, this equipment is widely applicable to high-end building decoration, luxury elevator door panels, high-end kitchenware and precision electronic components. Foshan City Ouyigang CNC Machinery Co., Ltd.sincerely welcomes customers from all walks of life to consult and negotiate — whether for processing with supplied materials or custom equipment, we will provide professional solutions and perfect after-sales service to achieve win-win cooperation.

The 1550 Type Coil Grinding 12K Mirror Production Line has set a new benchmark for green and efficient processing in the industry, winning wide market attention with its outstanding performance in efficiency, environmental protection and quality. Adhering to the business philosophy of "quality first, service first", we continuously optimize the equipment performance and provide customers with more competitive stainless steel mirror processing solutions. Choosing Foshan City Ouyigang CNC Machinery Co., Ltd.means choosing a reliable partner for enterprise development.