Introduction

In the ever - evolving world of metal processing, the demand for high - quality stainless steel products with excellent surface finishes has been on the rise. The abrasive belt stainless steel polishing machine has emerged as a crucial tool in meeting this demand. This article will explore the significance of this machine, especially in the context of Foshan Ouyigang CNC Equipment Co., Ltd., a leading player in the industry.

The Stainless Steel Surface Processing Industry Landscape

The stainless steel industry is a vast and dynamic sector. Stainless steel is widely used in various fields, from construction and architecture to kitchenware and automotive manufacturing, due to its corrosion - resistance, strength, and aesthetic appeal. However, to fully realize the potential of stainless steel, achieving the right surface finish is essential.

Surface finishes not only enhance the visual appearance of stainless steel products but also affect their functionality. A smooth, polished surface can improve corrosion resistance, reduce friction, and make cleaning easier. In recent years, with the increasing competition in the global market, manufacturers are constantly seeking more efficient and precise surface processing methods. This has led to the development and widespread adoption of advanced equipment like the abrasive belt stainless steel polishing machine.

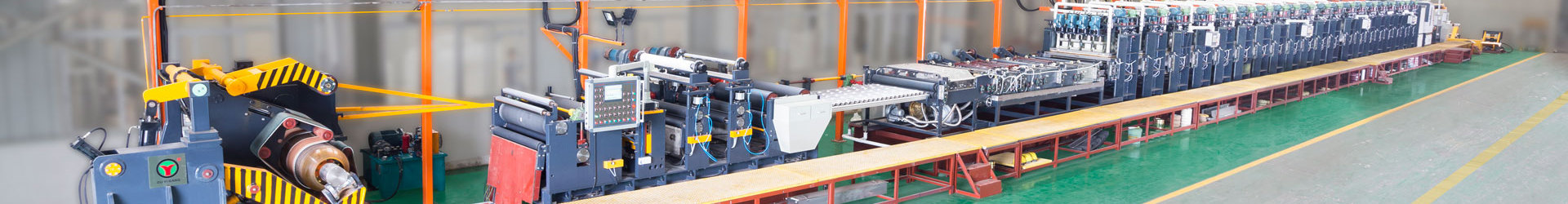

[Insert Image 1: A General View of a Stainless Steel Manufacturing Factory with Various Processing Equipment. The image shows a busy factory floor with stainless steel sheets being processed, giving a sense of the scale of the stainless steel industry. The abrasive belt polishing machines can be seen in the background, among other equipment.]

Working Principle

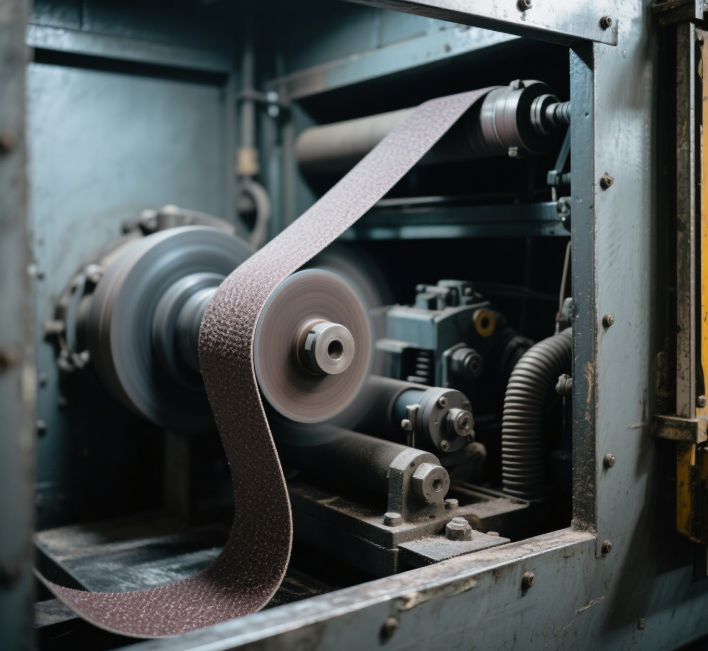

The abrasive belt stainless steel polishing machine operates based on a simple yet effective principle. It uses an abrasive belt, which is a flexible strip coated with abrasive materials such as aluminum oxide or silicon carbide. When the machine is in operation, the abrasive belt rotates at high speed and comes into contact with the stainless steel surface. The abrasive particles on the belt gradually remove the imperfections on the stainless steel, such as scratches, rust, and welding seams, while simultaneously polishing the surface to achieve the desired finish.

Different types of abrasive belts can be used depending on the specific requirements of the processing. For example, coarser - grit abrasive belts are suitable for rough grinding and removing large - scale defects, while finer - grit belts are used for final polishing to obtain a mirror - like finish.

Advantages over Traditional Polishing Methods

Compared to traditional polishing methods, such as manual polishing or using polishing wheels, the abrasive belt stainless steel polishing machine offers several distinct advantages.

Firstly, it significantly improves production efficiency. Manual polishing is a labor - intensive and time - consuming process, and the quality of the finish may vary depending on the skill level of the operator. In contrast, the abrasive belt polishing machine can work continuously at a high speed, achieving consistent results in a much shorter time.

Secondly, it provides a more precise and uniform surface finish. The mechanical operation of the machine ensures that the pressure applied to the stainless steel surface is consistent across the entire area being processed. This results in a more even finish, reducing the occurrence of uneven polishing or missed spots.

Thirdly, it is more cost - effective in the long run. Although the initial investment in an abrasive belt polishing machine may be relatively high, the savings in labor costs and the reduction in material waste due to more accurate processing can quickly offset this investment.

Company Overview

Foshan Ouyigang CNC Equipment Co., Ltd. was founded in 2000 and has since established itself as a leading enterprise in the production and manufacturing of mechanical equipment for stainless steel surface processing. It is a national high - tech enterprise integrating scientific research, design, production, sales, processing, and maintenance.

Over the past two decades, the company has adhered to a professional development path. With its leading scientific research and design capabilities, high - quality products, comprehensive one - stop service concept, and excellent management team, it has won wide acclaim in the market for stainless steel surface processing mechanical equipment. Its products are not only popular in the domestic market but also exported to Europe, America, Southeast Asia, Taiwan, and other parts of the world, winning a large number of loyal customers.

Technological Innovations

One of the key factors contributing to Ouyigang's success is its continuous focus on technological innovation. The company combines advanced foreign design concepts with cutting - edge technologies. For example, it has developed a patented CNC operating system using Siemens functions. This system endows the metal surface processing equipment with features such as automation, high efficiency, energy conservation, safety, and stability, which are in line with the future trends of the industry.

In the development of abrasive belt stainless steel polishing machines, Ouyigang has incorporated a series of innovative technologies. These include advanced belt - tensioning mechanisms to ensure the stable operation of the abrasive belt during high - speed rotation, and intelligent control systems that can adjust the processing parameters in real - time according to the characteristics of different stainless steel materials and processing requirements.

Applications of Abrasive Belt Stainless Steel Polishing Machine

Construction and Architecture

In the construction and architecture industry, stainless steel is often used for decorative purposes, such as in the design of handrails, facades, and interior fixtures. The abrasive belt stainless steel polishing machine can be used to create different surface finishes, from a brushed finish that gives a modern and industrial look to a high - gloss mirror finish that adds a touch of luxury. For example, in high - end commercial buildings, polished stainless steel elements can enhance the overall aesthetic and create a more sophisticated atmosphere.

Kitchenware and Appliances

Stainless steel is a popular material for kitchenware and appliances due to its hygienic properties and durability. Abrasive belt polishing machines are used to polish the surfaces of stainless steel cookware, sinks, and appliances. A smooth and polished surface not only makes these products more visually appealing but also easier to clean and maintain. For instance, polished stainless - steel sinks resist stains and are less likely to harbor bacteria, making them a preferred choice for modern kitchens.

Automotive Manufacturing

In the automotive industry, stainless steel is used in various components, such as exhaust systems, trim parts, and decorative elements. The abrasive belt polishing machine is used to improve the surface quality of these components. A polished stainless - steel exhaust tip can not only enhance the appearance of the vehicle but also reduce the risk of corrosion, ensuring a longer service life. In addition, the precise surface finish achieved by the polishing machine can improve the fit and performance of automotive parts.

Industry News and Trends

Advancements in Abrasive Materials

The development of new abrasive materials is one of the significant trends in the industry. Manufacturers are constantly researching and developing more efficient and durable abrasive materials. For example, the emergence of super - abrasive materials like cubic boron nitride (CBN) and diamond - coated abrasive belts has opened up new possibilities for processing hard and difficult - to - machine stainless steel alloys. These new materials can withstand higher temperatures and pressures during the polishing process, resulting in faster material removal rates and better surface finishes.

Environmental Considerations

With the growing global emphasis on environmental protection, the stainless steel surface processing industry is also taking steps to reduce its environmental impact. Abrasive belt polishing machines are being designed with more energy - efficient motors and better dust - collection systems. The use of water - based abrasive slurries instead of traditional oil - based ones is also becoming more common. These measures not only help to reduce energy consumption and pollution but also comply with increasingly strict environmental regulations.

Conclusion

The abrasive belt stainless steel polishing machine has become an indispensable tool in the stainless steel surface processing industry. Its ability to efficiently and precisely achieve high - quality surface finishes has significantly contributed to the development of various industries that rely on stainless steel. Foshan Ouyigang CNC Equipment Co., Ltd., with its long - standing experience, technological innovation, and commitment to quality, has played a leading role in promoting the application and development of these machines.

As the industry continues to evolve, driven by advancements in technology, changes in market demand, and environmental considerations, the abrasive belt stainless steel polishing machine will undoubtedly continue to be at the forefront of innovation. Manufacturers like Ouyigang will need to keep up with these trends and continuously improve their products to meet the ever - increasing challenges and opportunities in the global stainless steel market.